[Popular science] The correct repair and maintenance of fire-fighting equipment should be done in this way. Many people have made mistakes

Spot inspection and maintenance of NO.1 fire extinguisher

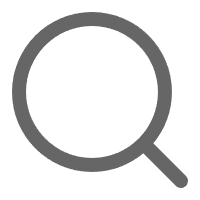

First, let's get to know the dry powder extinguisher:

Spot check of fire extinguisher:

(1) Check whether the pressure handle and lead seal are intact;

(2) Check whether the pointer of the pressure gauge points to the red area, if yes, it is abnormal;

(3) Check whether the hose and nozzle are free of damage and whether the nozzle is blocked;

(4) Check the bottle body for deformation, damage and serious rust;

(5) Check whether the fire extinguisher is within the validity period;

(6) Make spot inspection records.

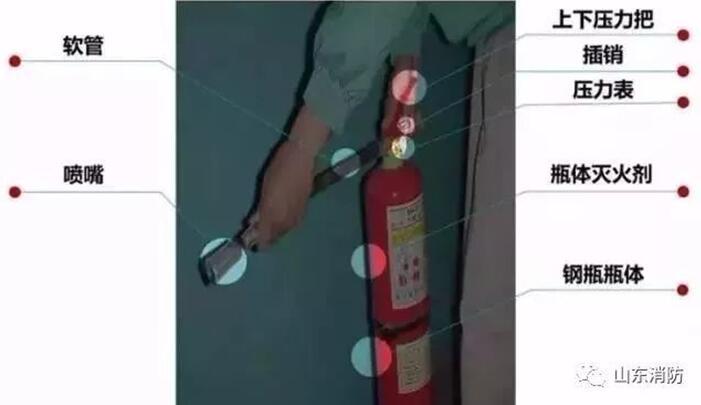

Use and maintenance of NO.2 indoor fire hydrant

Spot inspection of indoor fire hydrant:

(1) Check whether the fire hydrant box is deformed, whether the glass is damaged, and whether the door can be opened normally;

(2) Check whether the water gun and water hose are lost, whether the water hose is dry and damaged, whether its connector is firm and whether it can be put into use normally;

(3) Check the valve for water leakage;

(4) Visually check whether the alarm system is normally loaded;

(5) Make spot inspection records.

NO.3 Emergency lighting maintenance

Spot check of emergency lighting:

(1) Check whether the green working indicator works normally. If the red indicator is on, it is in the charging state. If the yellow indicator is on, there is a fault;

(2) Check whether the shell is damaged;

(3) Check whether the battery leaks;

(4) Unplug the power supply (or press the spot check button), check whether the emergency light can work normally, and restore the power supply if it works normally;

(5) If all the above inspection results are OK, sign on the spot inspection form of fire-fighting facilities for confirmation.

Maintenance of emergency light:

(1) It must be ensured to discharge and maintain the emergency lighting at least once a month (after disconnecting the power supply, it will naturally discharge completely and then plug in the power supply for charging);

(2) In case of any one or more problems found in the spot inspection of emergency lighting, timely repair or apply for replacement.

NO.4 Emergency exit light and evacuation indicator light

Spot check of emergency exit light and evacuation indicator light:

(1) Check whether the shell is damaged;

(2) Check whether the lamp is on normally.

Maintenance of emergency exits and evacuation indicators:

In case of any one or more problems found in the spot check contents of the emergency exit light and evacuation indicator light, repair or apply for replacement in a timely manner.

NO.5 Identification of various fire safety signs

(1) Intuitive viewing.

(2) Check whether there is dust on the surface and whether the chrome plate is clear. If there is dust, wipe it off in time.

(3) Manual experiment for viewing.

(4) Manually and directly start the fan in the fan room. After the operation is normal, check the power distribution device at the end of the fan, and check the switch test between the end and the fire host to see if it is normal.

(5) The smoke outlet shall be opened and closed manually, and shall be lubricated frequently to prevent corrosion.

(6) After closing and resetting, it shall be sealed well without gaps, and the smoke outlet and air supply outlet shall be installed firmly and reliably.

(7) The smoke exhaust fan shall be opened through fire control, and the exhaust and supply air volume shall meet the set requirements.

(8) After startup, the control center will have feedback signals. The wind speed should meet certain requirements. The air supply speed should not be greater than 7 meters per minute, and the smoke exhaust speed should not be greater than 10 meters per minute.

(9) The fan operates normally. After the feedback signal is input from the control center, the fan is stopped manually in the control room. After the sealing is reset, the manual operation is normal. After passing the above procedure, the fan is considered normal and the system is in good condition. In case of any fault, the Engineering Department can be notified immediately for maintenance.

Maintenance of NO.7 spray system

(1) The automatic sprinkler system is generally composed of sprinkler, pipe network, alarm valve, detector, alarm, accessories and accessories, and the maintenance of the above components can be focused.

(2) Check whether the nozzle is cracked, and do not let high-temperature objects close to the nozzle.

(3) Check whether there is any leakage in the pipe network to avoid false alarm. If there is a fault, notify the Engineering Department in time for maintenance.

(4) Open the end water test valve, the alarm will open automatically, and the water flow will enter the hydraulic alarm bell to send a signal.

Related news

——